- Home

- Products

- Laboratory Ventilation

- Autoclaves & Sterilizers

- Dental Autoclave

- Cassette Sterilizer

- Horizontal Autoclave

- Vertical Autoclave

- Pulse Vacuum Autoclave

- Portable Autoclave

- H2O2 Plasma Sterilizer

- Formaldehyde Steam Sterilizer

- Ethylene Oxide Sterilizer

- Hot Air Sterilizer

- Air Sterilizer

- Infrared Sterilizer

- Glass Bead Sterilizer

- Sealing Machine

- Automatic Biological Reader

- Autoclave Consumables

- Cold Storage Products

- Washer Disinfector and Cleaners

- Water Purification

- Incubators

- CO2 Incubator

- Constant-Temperature Incubator

- Constant Temp. & Humidity Incubator

- Biochemical Incubator

- BOD Incubator

- Shaking Incubator

- Anaerobic Incubator

- Mould Incubator

- Platelet Incubator

- Plant Growth Incubators

- Climate Incubator

- Medicine Stability Testing Chamber

- Incubator/Drying Oven(Dual-use)

- Automatic Egg Incubator

- Aging Test Instruments

- Battery Stability Test Chamber

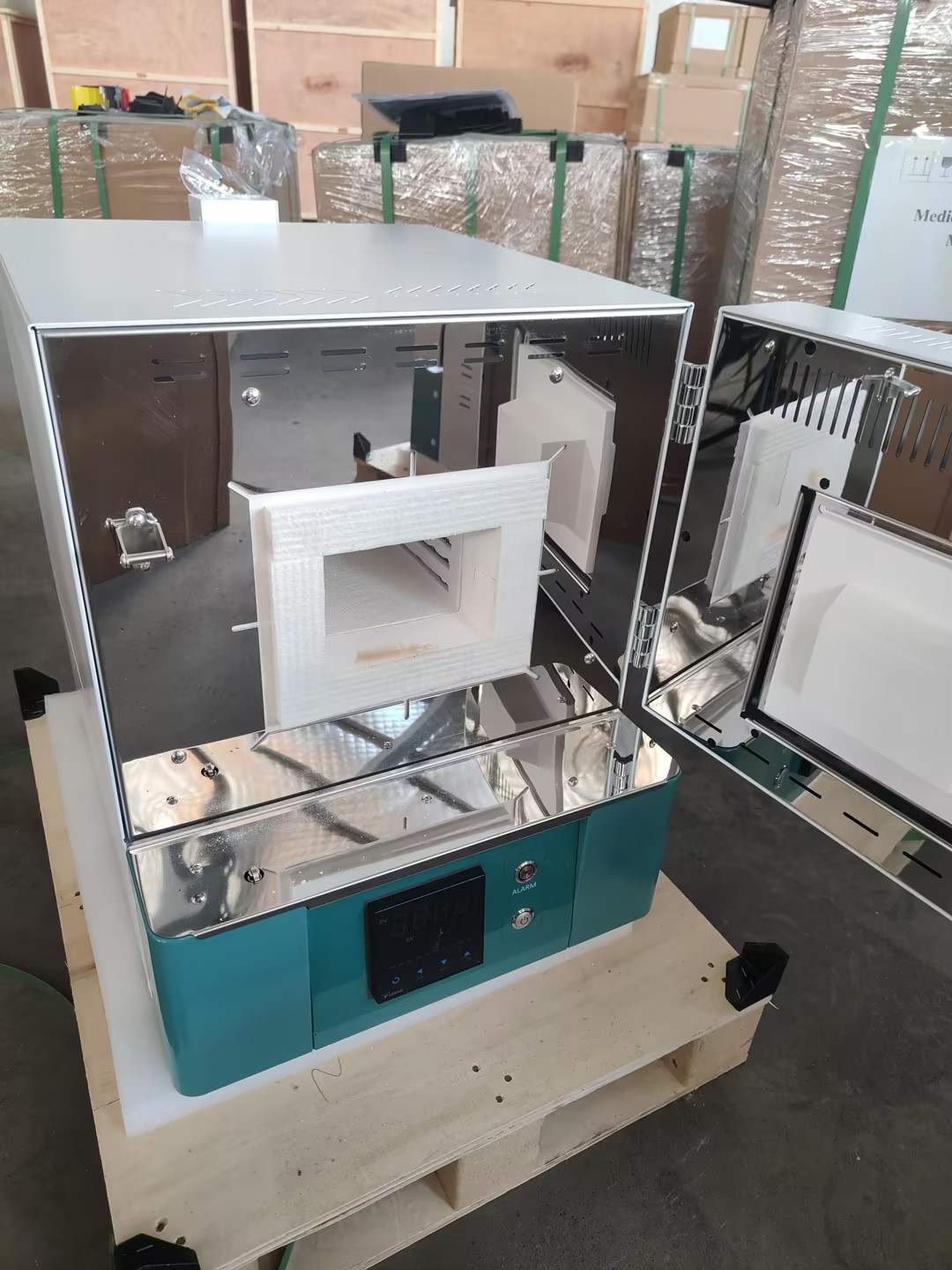

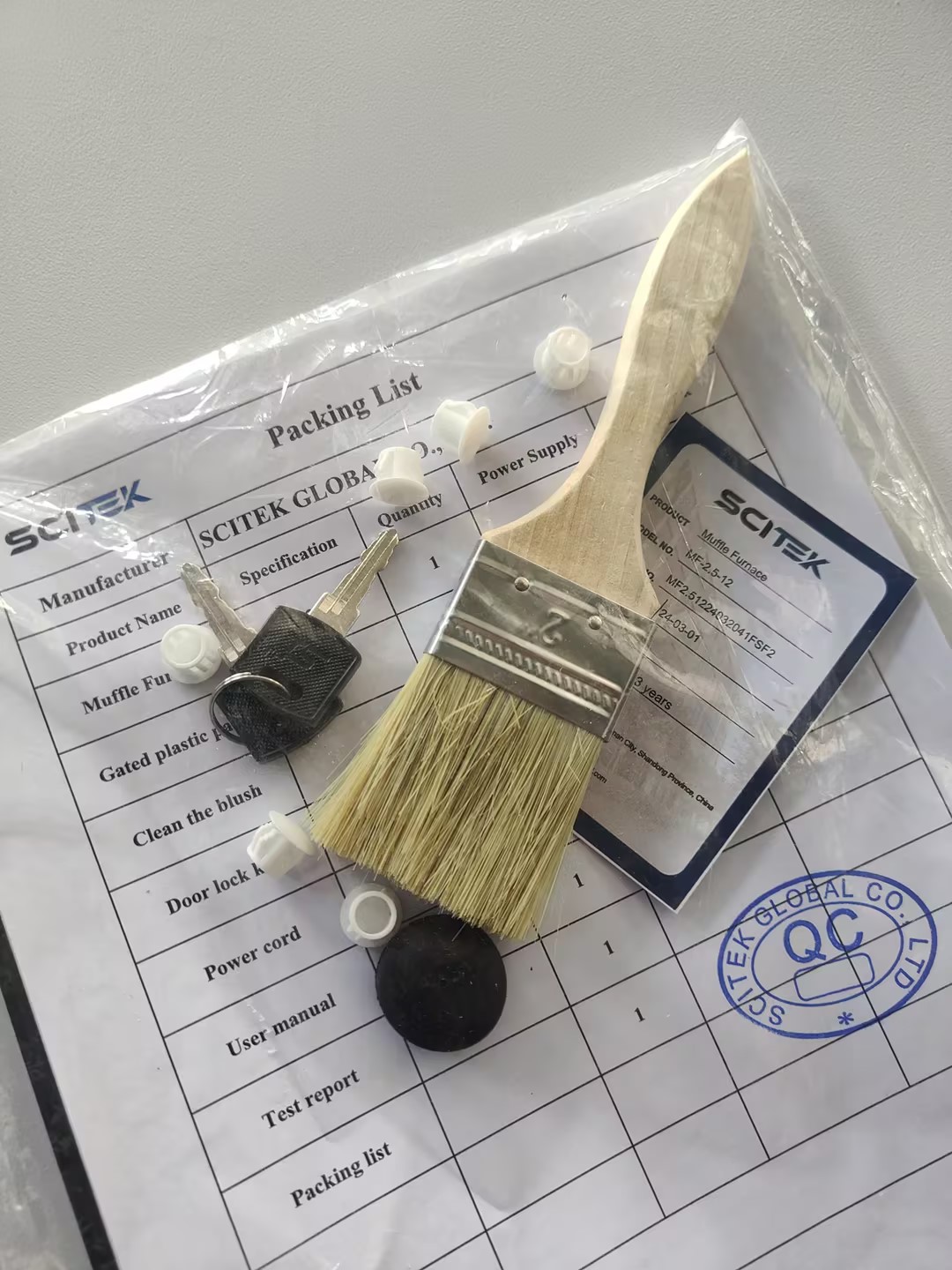

- Ovens and Furnaces

- Centrifuges

- Balances and Scales

- 0.00001g/0.0001g Semi-micro Analytical Balance

- 0.0001g Electronic Analytical Balance

- 0.001g Electronic Analytical Balance (External Calibration)

- 0.01g Electronic Analytical Balance (External Calibration)

- 0.1g Electronic Balance

- Halogen Moisture Analyzer

- Electronic Platform Scale

- Electronic Counting Scale

- Spectrophotometer and Colorimeter

- Microscopes

- Mixer and Shaker

- Hotplates and Stirrers

- Water Bath

- PH And Electrochemistry

- Elisa Reader and Washer

- PCR Analyzer and Pretreatment

- Electrophoresis

- Organic Element Analysis and Pretreatment

- Microwave Digestion

- Physical Measurement

- Automated External Defibrillator

- Histology and Cytology

- Clinical Analyzers and Reagents

- Dental Clinical

- Medical Device

- Blood Bank Equipment

- Chromatography Systems

- Lab Gas Generator

- Concentrator

- Evaporators and Chillers

- Grinding and Polishing Machine

- Lab Mills and Vibrating Sieve

- Microbiological Equipment

- Ultrasonic Cell Disruptor

- Freeze Dryer

- Ice Maker

- Lab Analysis Equipment

- Pipettes and Dispensers

- Filtration Apparatus & Consumable

- Pumps

- Pharmaceutical Equipment

- Seal Integrity Testing

- Animal Housing & Care Equipment

- Agricultural Lab Solution

- Alveograph

- Amylose Tester

- Chlorophyll Concentration Meter

- Electronic Extensograph

- Falling Number Meter

- Flour Checking Sieve

- Flour Quality Analyzer

- Fruit Sclerometer

- Gluten Tester

- GPS Area Meter

- Grain Hardness Meter

- Grain Moisture Meter

- Leaf Thickness Gauge

- Leaf Area Meter

- Pest Killing Lamp

- Pesticide Residue Meter

- Plant Canopy Analyzer

- Plant Nutrition Analyzer

- Plant Photosynthesis Meter

- Plant Porometer

- Plant Transpiration Rate Meter

- Sample Mill

- Seed Counter

- Soil Compaction Tester

- Soil Irromerter Tensiometer

- Soil Moisture Meter

- Soil Nutrient Tester

- Soil pH-Moisture Meter

- Soil Respiration Meter

- Soild Tester

- Weather Monitor System

- Wheat Thresher

- Clean Room Project

- Environment Monitor

- Lab Burner

- Solutions

- About Us

- EXPOS

- News

- Contact

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English